Enhance Reliability and Productivity: Update Your Equipment with Top Quality Mining Equipment Parts

Enhance Reliability and Productivity: Update Your Equipment with Top Quality Mining Equipment Parts

Blog Article

Unveiling Necessary Mining Equipment Components for Ideal Operations

In the detailed world of mining operations, the smooth performance of devices is extremely important. As we dive into the depths of mining equipment essentials, a more detailed look at the detailed details and performances of these components reveals an interesting globe where effectiveness and reliability are the keystones of success.

Significance of Correct Drill Bits

Appropriate option and upkeep of drill little bits are fundamental for maximizing mining efficiency and productivity (mining equipment parts). The type of drill bit chosen need to straighten with the details geological problems of the mining website to make sure optimum efficiency.

Routine upkeep of drill little bits is just as vital to ensure durability and performance. Dull or damaged drill little bits can bring about reduced exploration speed, increased wear on drilling tools, and inevitably, decreased efficiency. Upkeep jobs might include sharpening, regrinding, or changing used parts to keep the drill little bits in leading working condition.

Key Parts in Conveyor Solutions

Reliable product transportation in mining operations greatly relies upon the functionality and honesty of crucial components in conveyor systems. One important component is the conveyor belt itself, which carries the products along the mining site. The top quality and resilience of the conveyor belt are vital to protect against failures and guarantee a smooth flow of products. An additional crucial component is the idler, which supports the conveyor belt and helps preserve correct tension for reliable operation. Idlers are purposefully put along the conveyor system to reduce rubbing and sustain the weight of the materials being moved - mining equipment parts.

Important Filters for Equipment Upkeep

A vital facet of making certain the long life and optimum efficiency of mining devices lies in the precise selection and maintenance of crucial filters. Filters play a vital function in securing mining machinery from contaminants that can create damage, bring about pricey fixings and downtime. Dust, dust, and debris are prevalent in extracting atmospheres, making the appropriate filtration system important to devices sturdiness.

Filters in mining equipment offer to catch particles that can penetrate sensitive parts such as transmissions, hydraulics, and engines. Regularly changing these filters according to investigate this site maker suggestions is vital to stop clogging and make sure efficient procedure. Overlooking filter upkeep can result in lowered equipment life-span, lowered performance, and increased gas consumption.

Essential Use Components for Crushers

In the realm of mining devices upkeep, one crucial facet that requires attention is the recognition and replacement of vital wear components for crushers. Crushers play an essential role in the ore handling and worldly Recommended Site reduction procedures within mining procedures. Some of the crucial wear parts that are vital for the reliable functioning of crushers include the complying with:

** Crusher Liners **: These are critical in protecting the crusher covering from damage caused by the material being crushed.

** Jaw Plates **: Established in jaw crushers, these components are in charge of squashing the product versus a fixed surface.

** Mantles and Concaves **: These components are important in gyratory crushers, where they assist in squashing the material right into an extra polished kind.

Normal examination and substitute of these wear components are crucial to make certain the crushers run at their optimum efficiency, minimizing downtime and making best use of performance in mining procedures. Correct upkeep of these wear components can substantially influence the overall performance and durability of the crushers, inevitably adding to the success of mining activities.

Function of Hydraulic Cyndrical Tubes in Mining

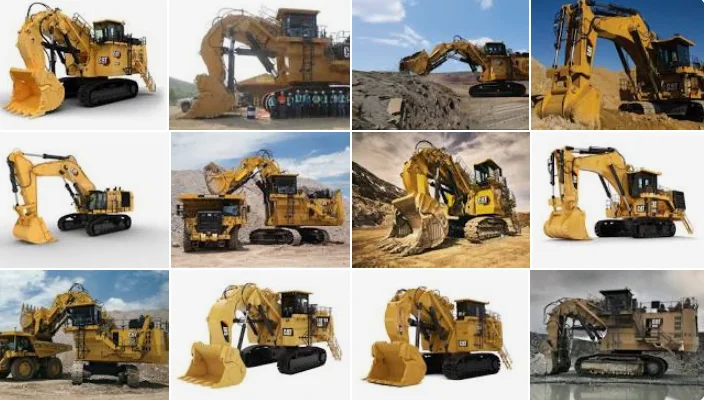

Playing a pivotal role in contemporary mining procedures, hydraulic cylinders are essential components that help with the efficient functioning of numerous heavy equipment. These hydraulic cyndrical tubes are important for powering vital mining equipment such as excavators, loaders, bulldozers, and drills. Among the main functions of hydraulic cyndrical tubes in mining is to supply the force needed to move hefty lots and products in tough terrains. The capacity of hydraulic cyndrical tubes to generate immense power in a regulated manner makes them vital for jobs like lifting, pushing, drawing, and crushing within mining procedures.

Hydraulic cylinders in mining equipment are developed to hold up against harsh operating problems, including severe temperature levels, high pressures, and hefty loads. In significance, hydraulic cylinders play a vital role in boosting the effectiveness and efficiency of mining procedures worldwide.

Conclusion

Finally, it is vital for extracting operations to utilize correct drill bits, crucial parts in conveyor systems, vital filters for devices maintenance, crucial wear components for crushers, and hydraulic cylinders. These necessary mining equipment parts play a substantial role in guaranteeing optimal operations and maximizing performance in the mining market. By investing in dependable and top quality equipment components, mining firms can improve efficiency and lessen downtime, eventually causing an extra effective operation.

In the elaborate world of mining operations, the smooth performance of check my site tools is paramount. By investing in premium filtration systems and adhering to a stringent upkeep routine, mining operations can boost devices reliability, lessen downtime, and inevitably maximize efficiency.

In the world of mining devices maintenance, one crucial element that demands interest is the identification and replacement of essential wear components for crushers. These essential mining equipment components play a considerable duty in optimizing and guaranteeing optimum operations performance in the mining market. By spending in top notch and reputable tools components, mining business can boost performance and reduce downtime, inevitably leading to a much more effective procedure.

Report this page